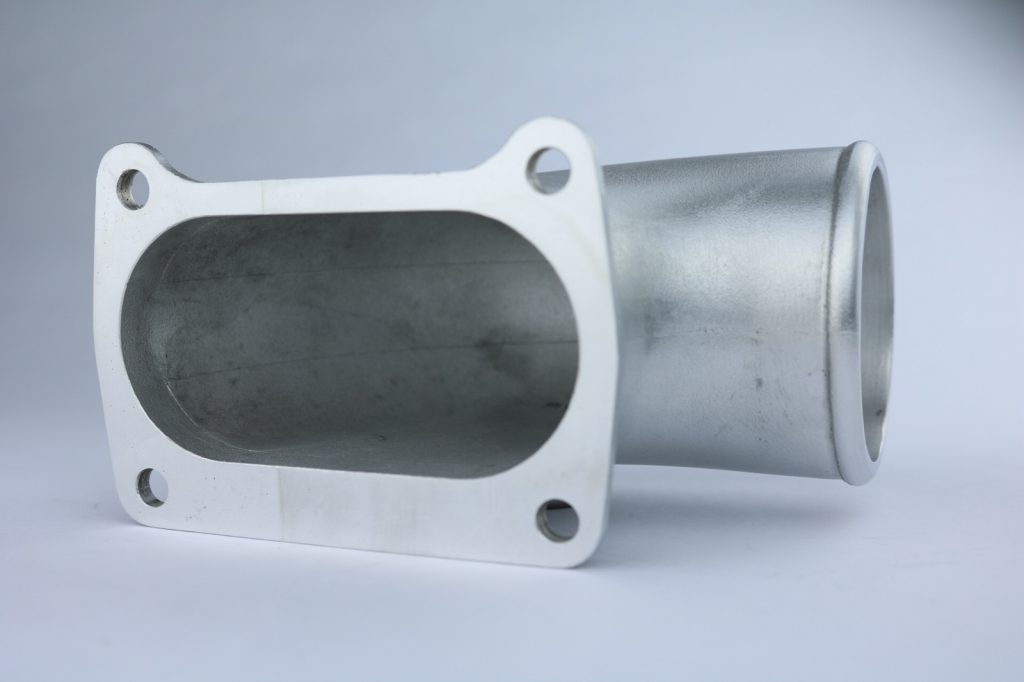

Investment casting or 'lost wax processing' provides a shortcut to your finished precision parts without welding, excessive machining or assembly. It is the solution for many complex shapes and provides smooth surface finishes, accurate dimensions and fine detail. Some of the advantages found in the investment casting process design flexibility, alloy choice, lower production costs, machined to print, and no assembly required.

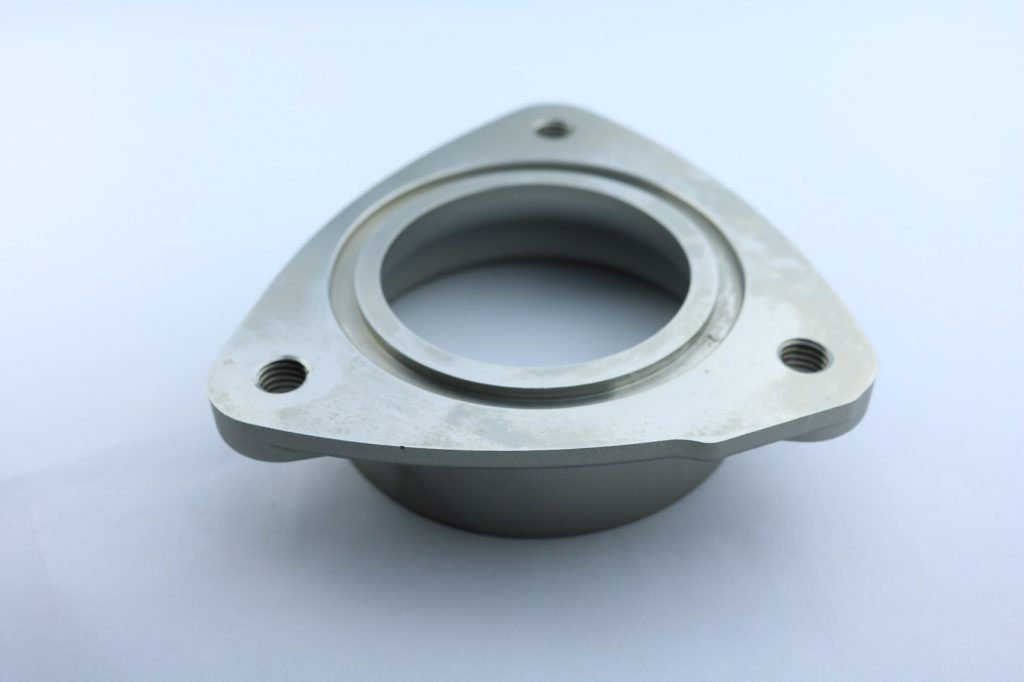

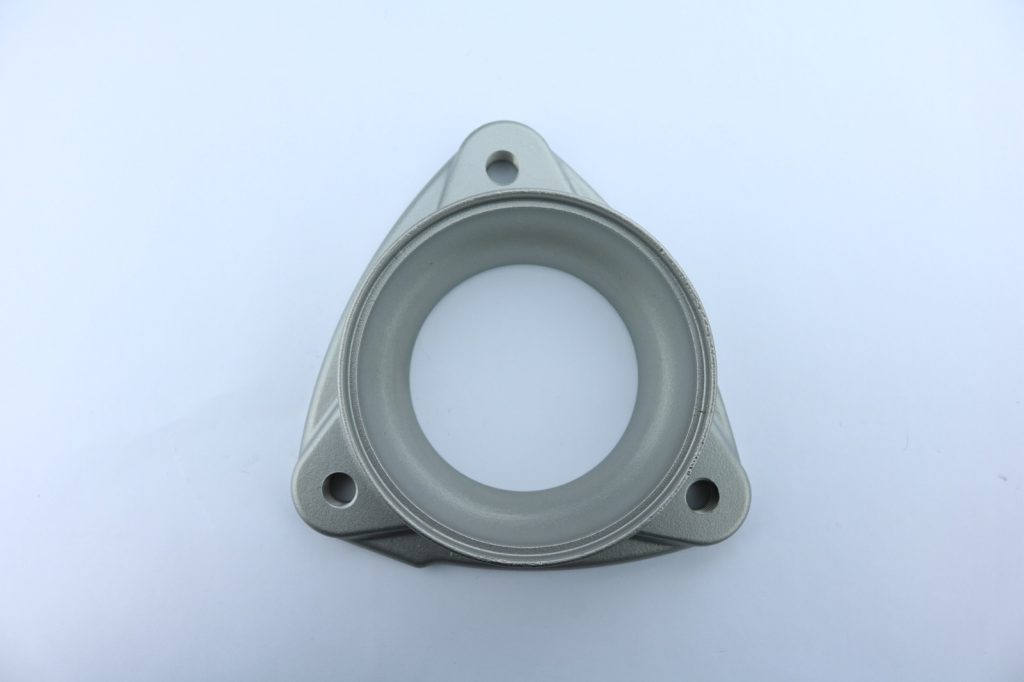

Because the investment casting process produces "near net shape" configurations, we are able to meet the specifications that you request to almost perfect detail. They are capable of producing precise detail and accuracy in all parts. Skat-Trak chooses to make products with the finest materials around. We use 17-4 stainless steel. It all starts with quality ingredients. Our machine shop can also machine your casting to make it one less step you have to worry about.

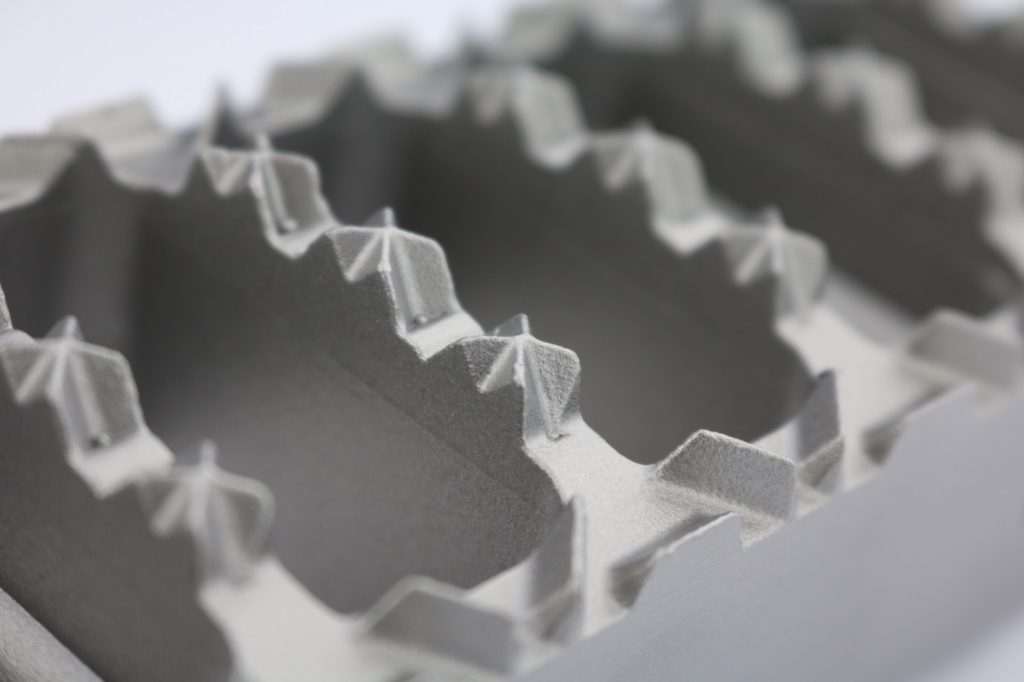

Investment casting process has the design freedom that affords engineers and designers to design complex shapes, tight dimensions, repeatability from part to part, an incredible surface finish, and a variety of alloy choices. Thus, making investment casting a very cost effective solution.

Common applications for investment castings include jewelry, metal golf clubs, internal combustion engines, and many parts in jet engines. Skat-Trak specializes in automotive, watercraft, commercial & industrial casting applications, as well as aerospace.

Skat-Trak has our aluminum foundry that is able to make bulk product for our customers. The plaster is poured over the pattern and the unit shaken so that the plaster fills any small features. The plaster sets, usually in about 15 minutes, and the pattern is removed. The dried mold is then assembled, preheated, and the metal poured. Finally, after the metal has solidified, the plaster is broken from the cast part. Skat-Trak uses 356 and 713 Tenzaloy aluminum.

Skat-Trak has our machine shop that is able to finish castings to your specifications allowing you to have a One-Stop-Shop for all your casting and machining needs.

Our Equipment Includes:

- TEN Mazak CNC Quick Turns Lathes

- TWO Mazak CNC 250 M Turning and Milling Quick Turn Lathes

- Mazak Nexus 410A 4-Axis Vertical Mill

- THREE Conventional Lathes

- TWO Conventional Mills

Let us help you cast and machine your product.

Skat-Trak provides a wide selection of alloys to our customers. Below is a partial list of the alloys that we regularly pour:

- Stainless steels

- Aluminum

- Mn Bronze

- Tenzaloy 713

- ALMAG 535

If you do not see your alloy listed above, please contact us and we can talk about the specific alloy that you are interested in.